FRNSW hose connections

Hose connections on fire hydrant and fire sprinkler systems are required to be compatible with Fire and Rescue NSW (FRNSW) equipment. The hose connections may be either Storz or NSW Fire Brigade Thread (FBT).

For building owners and managers

Any fire hydrant or fire sprinkler system installed in a premises must have compatible inlets and outlets fitted (i.e. hose connections). The inlets and outlets are compatible if they comply with a standard to which they were designed, installed and commissioned.

If non-compatible hose connections are installed, it is the owner’s responsibility to have them replaced with compliant ones. The owner should engage a fire protection company to install compliant hose connections within a reasonable time frame. FRNSW recommends engaging a fire protection company that is a member of a nationally recognised professional body or organisation and agrees to a fire protection industry code of conduct.

Fire brigade booster inlets

For systems installed pre-2008, fire brigade booster inlets may comprise a female dynamic joint having fire brigade thread (FBT). These do not need to be upgraded with Storz hose connections unless the entire booster system is being modified or upgraded.

For systems installed or modified post-2008, fire brigade booster inlets should comprise an NEN 3374 ‘permanent pressure coupling’ (i.e. forged Storz hose connection with BSP thread). The Storz hose connection may have either a male or female thread.

For newly installed or modified systems (i.e. post 2022), fire brigade booster inlets should comprise an AS 2419.4 Storz hose connection.

Fire hydrant valve outlets

For systems installed pre-2008, fire hydrant valve outlets may comprise male FBT outlet. These do not need to be upgraded with Storz hose connections unless the entire hydrant system is being modified or upgraded.

For systems installed or modified post-2008, fire hydrant valve outlets should comprise either existing male FBT outlet fitted with a forged FBT-Storz adaptor,

or an NEN 3374 ‘permanent pressure coupling’ (i.e. forged Storz hose connection with BSP thread).

For newly installed or modified systems (i.e. post 2022), fire hydrant valve outlets should comprise an AS 2419.4 Storz hose connection.

Do I need to upgrade my hose connections?

Fire hydrant and fire sprinkler systems which have FBT hose connections do not need to be upgraded to Storz, unless the entire system is being modified or upgraded by way of a fire safety order issued by a regulatory authority (e.g. Council) or through voluntary building modification, extension or alteration (e.g. development application process).

AS 2419.1-2005 stated both FBT and Storz hose connections were acceptable in NSW. In 2008 FRNSW published a technical information sheet which specified the fitting of a forged aluminium FBT-Storz adaptor to the fire hydrant system of any new development.

Appendix Q of AS 2419.1-2021 identifies that new hose connections must be compatible with AS 2419.4 (i.e. Storz).

However, if any non-compatible Storz hose connections are identified on your system, they should be replaced with compliant Storz hose connections.

Are my Storz hose connections compatible with FRNSW equipment?

To be compatible with FRNSW equipment, hose connections are required to have a form, fit and function that is equivalent to the Storz hose couplings fitted to firefighting hoses used by FRNSW. This means having a 65 mm Storz hermaphrodite hose connection complying with AS 2419.4 or an FBT-Storz adaptor suitable for firefighting application, as detailed in FRNSW compatible hose connections.

AS 2419.4 is the contemporary Australian Standard equivalent to NEN 3374:1971 Fire fighting equipment – Fire hose couplings and ancillary equipment, the previous applicable standard. NEN 3374 is a Dutch standard originally nominating dimensions for 65 mm Storz. However, materials and method of manufacture were done to DIN (German) standards not referenced by the 1971 Dutch standard – there is no 65 mm DIN hose connection because this diameter connection is not used by German fire services.

The Storz hose connection can be either forged aluminium or copper alloy. Cast aluminium Storz hose connections are not premissible under any circumstance as they are not rated for firefighting pressures; they will need to be replaced with compliant Storz hose connections.

For fire protection installers and maintainers

Fire protection installers and maintainers must ensure only compliant hose connections are purchased and installed. Generally, only reputable firefighting equipment manufacturers produce Storz hose connections that meet a standard. Purchasing cheap low-quality connections to minimise costs is likely to result in costly rectification works being ordered by a certifier or regulatory authority.

It should be noted that FBT used by FRNSW is unique and is based on the London 'V‘ thread, being a 51/5 TPI Whitworth form thread. The FBT-Storz adaptor is therefore produced exclusively for firefighting use in NSW. However, some FBT-Storz adaptors sold in NSW did not meet any minimum standard, hence the transition to AS 2419.4 hose connections in the latest NCC and its referenced Australian Standard.

For manufacturers and suppliers

FRNSW use Storz hermaphrodite hose couplings manufactured to comply with AS 2419.4. Storz hose connections are to be manufactured to this standard or equivalent.

Note: Reference should be made to Appendix A of AS 2419.4 for documentation of product conformity. A simple letter of conformity from the manufacturer or supplier is not adequate; independent testing demonstrating product conformity should be able to be provided.

For certifiers

Certifiers should verify Storz hose connections are compliant before issuing any occupation certificate.

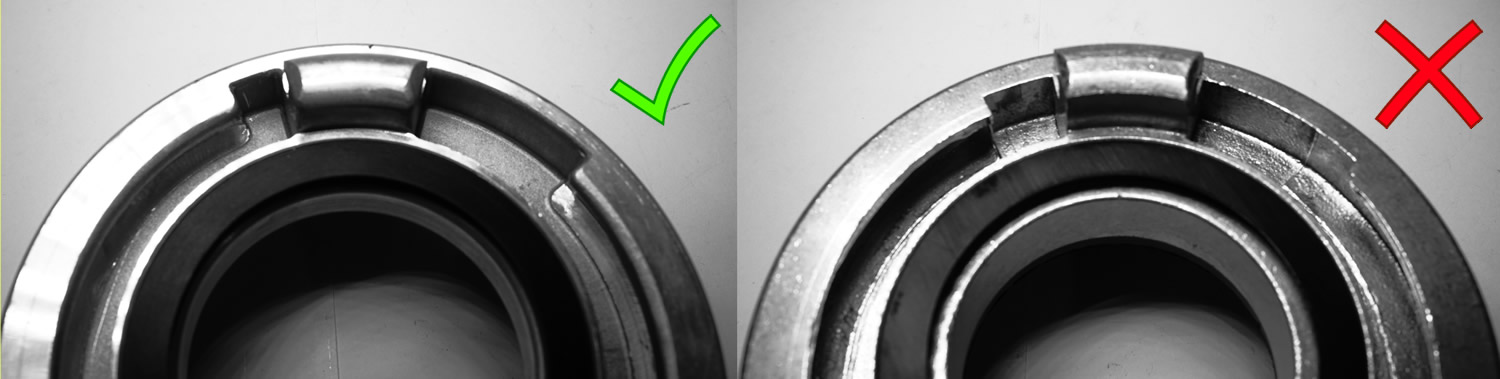

A professional body such as the Fire Protection Association Australia can assist with providing information on suppliers of compliant Storz hose connections from reputable manufacturers. Generally, a compliant hose connection can be identified by having a high quality machined finish relatively free of imperfections (e.g. chipped edges, soft dents/scratches evident, mottled finish, pocked or pitted appearance, matt lustre to machined surfaces, or being dip-coated and shiny).

A compliant hose connection will also have a proper forging mark indicating that a registered forger has been used to temper the Storz hose connection to a certified temper process.

If a certifier has any hesitation, they should request documentation as outlined in Appendix A of AS 2419.4 to be provided from an independent testing body accredited for product certification. If doubts remain, refer to FRNSW for further advice.

Further information

FRNSW compatible Storz hose connections (Adobe, 972 kb pdf)

Inspecting hose connections on hydraulic fire safety systems (Adobe, 1.4 mb pdf)